- Home

- »

- 2 Shot Injection Molding

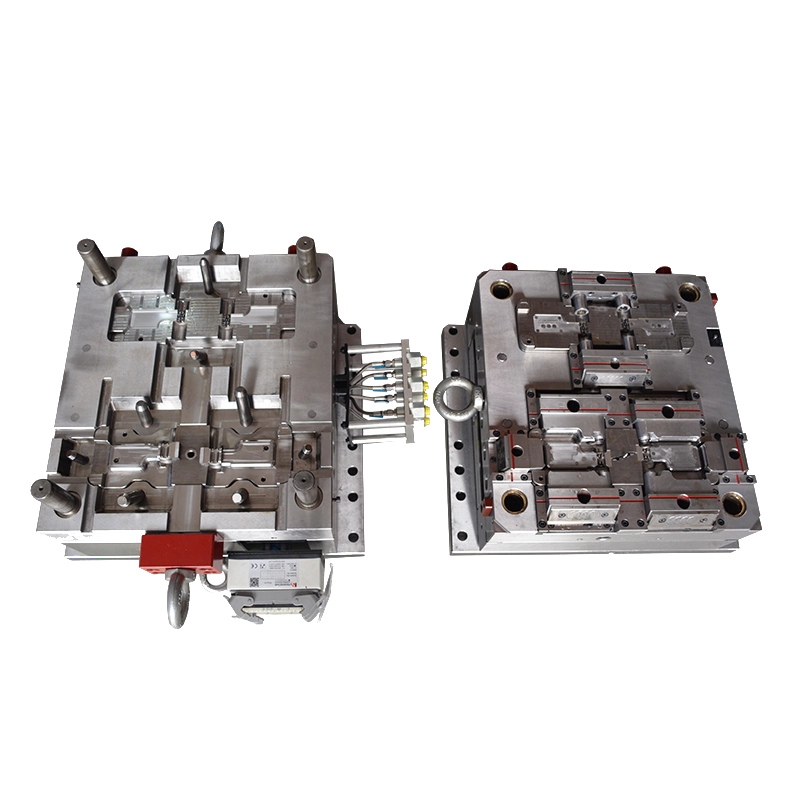

2 Shot Injection Molding: Precision Dual-Material Solutions by GBM-Mould

One Cycle, Two Materials, Zero Compromises — Solve Assembly & Bonding Pain Points

- No Secondary Assembly

- Strong Dual-Material Bonding

- ISO Certified 2 Shot Molding

Get detailed quote + free DFM review in 12 hours

2 Shot Injection Molding Services

Founded in 2010, we provide end-to-end 2 shot molding solutions — from prototype sampling to mass production, our services are customized to match your project’s unique stage and requirements. Benefit from precision two shot molds, dual-material expertise, and reliable lead times for automotive, electronics, and medical applications.

| Service Type | Application Scenarios | Lead Time | Typical Material Combinations | Core Advantages |

|---|---|---|---|---|

| 2 Shot Molding Prototype Service | Small-batch sampling, design validation | 7-10 days | ABS+PP, PC+ABS | Fast design validation, low cost |

| Mass Production Service | Large-volume orders, long-term supply | 15-20 days | ABS+TPU, PC+TPE, PP+TPE | 99.8% pass rate, stable capacity |

| Custom Two Shot Mold Service | New product mold development, mold upgrade | 10-14 days | Mold materials: S136, H13, 718H | Tolerance ±0.01mm, mold life ≥500k shots |

| Medical-Grade 2 Shot Molding | Medical devices (handles, connectors) | 18-25 days | Medical PP+TPE, PC+silicone | ISO13485 certified, biocompatible |

| 2 Shot Overmolding Service | Soft-touch components (handles, seals) | 12-18 days | Rigid base + soft layer | High bonding strength |

Core Application Fields of 2 Shot Injection Molding

Explore how GBM-Mould’s 2 shot injection molding solutions serve key industries. We deliver tailored dual-material components — from automotive interior parts to medical device handles — combining precision, durability, and compliance to meet diverse sector demands.

Automotive Industry

We provide 2 shot injection molding solutions for door handles, sensors, dashboard buttons. Our 2 shot plastic components deliver key value: lightweight design, durable dual-material bonding, seamless assembly-free integration — ideal for New Energy Vehicle 2 shot parts and Automotive Interior 2 shot components.

Electronics Industry

Our 2 shot injection molding services cover charger housings, connectors, and switch shells. These precision 2 shot plastic parts feature insulation-grade dual-material combinations and impact-resistant 2 shot overmolding, perfectly matching 5G Device 2 shot components and Smart Wearable 2 shot parts.

Medical Industry

We offer 2 shot injection molding for device handles and disposable components. Our offerings prioritize biocompatible 2 shot materials and ISO13485-certified 2 shot molding, serving as reliable Medical Device 2 shot components and Disposable 2 shot supplies.

What is 2 Shot Injection Molding?

2 shot injection molding (two shot molding) is a advanced process that forms a single component with 2 different materials/colors in one production cycle. It eliminates secondary gluing/assembly (cutting labor cost by 50%+), achieves seamless bonding, and supports combinations like rigid ABS+soft TPU or transparent PC+opaque PP. Backed by specialized 2 shot machines and precision molds, it meets the high demands of automotive, electronics, and medical industries .

- Step 1: Inject first material into 2 shot injection molding machine cavity.

- Step 2: Rotate two shot mold to align base with second cavity.

- Step 3: Inject second material for 2 shot overmolding.

- Step 4: Eject finished part from 2 shot injection mold.

Expert Bonding Solutions

The core of a successful 2 shot molding process is the molecular fusion between resins. We utilize specialized chemical primers and mechanical interlock designs (like swallow-tail or undercut structures) to ensure 100% adhesion for complex material pairs such as PC+TPU and ABS+TPE. Our engineering team precisely optimizes the melt temperature for each shot to guarantee long-term structural integrity and prevent delamination.

Precision Quality Control

Unlike standard two shot injection molding companies, we provide full engineering transparency through data. Equipped with Mirror EDM achieving Ra 0.1um surface finish, our facility ensures impeccable aesthetics for optical and automotive parts. Every project includes a comprehensive CMM dimension report and CPK study, guaranteeing that your high-tolerance multi-material components meet the strictest industry standards.

Advanced Tech & Equipment: The Core of Precision Molding

At GBM Mold, our superior precision relies on industry-leading technology. We integrate high-end 5-axis machining, 1,100T large-scale injection, and Mirror EDM to deliver consistent, high-accuracy solutions for complex 2-shot projects.

Expert Tooling Fabrication

We utilize premium Yamazen/YCM 5-axis CNC systems (15,000-24,000rpm) and AgieCharmilles Wire EDM to achieve ±0.001mm precision. Our facility is engineered to handle complex geometries and heavy-duty 5.5-ton mold bases, ensuring structural stability for large-scale projects.

Mastering Surface & Accuracy

Quality is guaranteed through Hexagon CMM automated inspection and Mirror EDM processes that achieve an optical-grade Ra 0.1μm surface finish. We provide comprehensive 3D inspections, FAI, and CPK reports to maintain high-tolerance consistency across every multi-material component.

High-Volume 2-Shot Production

Featuring Fanuc and Haitian machines, we provide a massive 1,100T dual-injection capacity for complex automotive and transparent components. Our scientific molding ensures 100% bonding integrity with a rapid 4-week lead time from DFM approval to T1 samples.

Beyond Standard Molding: How GBM Solves Your Toughest 2K Challenges

| Customer Pain Points | GBM’s 2-Shot Injection Molding Solutions | Your Bottom-Line Benefits |

|---|---|---|

| Delamination & Weak Bonding | We utilize professional Material Compatibility Analysis and specialized two shot overmolding techniques to ensure a perfect chemical or mechanical bond between substrates. | 100% Leak-proof & Durable: No peeling or separation, even in harsh environments. |

| High Assembly Costs & Errors | Our 2 shot molding process integrates two materials into one part during a single cycle, eliminating the need for secondary manual assembly. | Significant Cost Savings: Reduce labor costs by up to 50% while improving part consistency. |

| Technical Design Risks | Every project starts with a Free DFM & Moldflow Analysis. Our 20-year engineering team predicts sink marks, air traps, and gate balance issues before cutting steel. | Risk-Free Production: Zero wasted investment on "un-moldable" designs; optimized for high-volume efficiency. |

| Capacity & Scalability Issues | Equipped with a massive 1,100-Ton 2-shot injection molding machine, we can produce large automotive or industrial parts weighing up to 5.5 tons. | Unlimited Scalability: One partner to handle everything from micro-components to large-scale parts. |

| Missed Market Deadlines | We maintain a 96% on-time T1 sample rate. Our project management ensures stack molds and 2K tools are ready for shipment in record time. | Faster Time-to-Market: Stay ahead of your competitors with reliable, fast project delivery. |

2-Shot Injection Molding: Knowledge Base & FAQ

At GBM, we are dedicated to providing high-precision 2-shot injection molding solutions that withstand complex engineering requirements. Our integrated process utilizes advanced multi-component technology and specialized machinery to ensure superior bonding, aesthetic excellence, and long-term durability.

Table of Contents

What is the difference between two-shot and overmold?

What is the difference between two-shot and insert molding?

What is the double-shot process?

- 1. First Shot

- 2. Mold Rotation

- 3. Second Shot

- 4. Finished Ejection

What is 2K and 3K molding?

What is the difference between two-shot and overmold?

What is the difference between two-shot and overmold?

Two-shot molding is an automated, single-cycle process using a rotating mold, while overmolding is a two-step process where a second layer is molded over a pre-existing part.

| Feature | Two-shot | Overmolding |

|---|---|---|

| Cycle | Single automated cycle | Two separate steps |

| Machine | Specialized 2-shot machine | Standard molding machine |

| Tooling | Complex rotating mold | Standard mold |

| Volume | Best for high volume | Best for low-to-mid volume |

What is the difference between two-shot and insert molding?

Insert molding combines plastic with non-plastic components (like metal) placed into the mold first. Two-shot molding combines two plastic resins in one continuous process.

Core Differences:

Material Interaction :

Insert Molding: Focuses on encapsulating pre-manufactured components such as brass inserts or magnets.

Two-Shot: Focuses on the chemical compatibility and molecular bonding of two resins, such as PC and TPU.

Operational Efficiency:

Insert Molding: Features a slower production cycle due to the time required to manually or robotically place inserts into the mold cavity.

Two-Shot: Enables high-speed, continuous production as the machine handles material transfer internally during the molding cycle.

What is the double-shot process?

The double-shot process uses two independent injection units on one machine. The mold plate rotates (or a slide moves) to allow the second material to be injected onto the first, still-warm part.

Primary Material Injection: The first material is injected to form the structural “skeleton” or substrate.

Precision Mold Indexing: The mold platen rotates 180° with micro-precision to align the substrate with the second cavity.

Secondary Material Overmolding: The second resin (often a different color or softer TPE) is injected. The heat from the second shot helps create a permanent molecular bond.

Automated Ejection: The finished part is ejected, often directly onto a conveyor, requiring no secondary labor.

What is 2K injection molding?

2K (Two-Component) molding is the industry standard for producing high-quality, multi-functional parts in a single operation. It eliminates assembly costs and improves the aesthetic and tactile quality of the product.

Enhanced Functionality: Combine a rigid housing with a soft-touch seal or a vibration-dampening grip.

Part Consolidation: Turn a multi-part assembly into a single, unified component.

Tighter Tolerances: Since the part never leaves the mold, the alignment between materials is nearly perfect.

Zero Secondary Assembly: Drastically reduces labor and inventory costs.

What is 2K and 3K molding?

2K and 3K refer to the number of resin components injected. 3K (triple-shot) is significantly more complex, allowing for three colors or three distinct material properties (e.g., hard base, clear window, soft seal) in one part.

| Type | Material Combo | Application Examples |

|---|---|---|

| 2K Molding | Hard Plastic + Soft Rubber | Power tool grips, toothbrushes, dual-color bezels. |

| 3K Molding | Rigid + Transparent + Elastomer | Automotive tail lights, complex medical housings. |

| Equipment | 2 Injection Units | 3 Injection Units & complex rotating tools. |