- Home

- »

- ABS Injection

Custom ABS Injection Molding Services: 16 Years of Precision Engineering

High-impact, durable ABS parts tailored for global industries. GBM delivers ±0.05mm tolerance and a 96% T1 success rate with expert solutions in automotive and medical manufacturing.

Get detailed quote + free DFM review in 12 hours

Expert Solutions for Critical ABS Molding Challenges

ABS is a versatile material, but achieving a perfect balance between dimensional precision and aesthetic excellence requires deep engineering know-how. At GBM, we leverage 16 years of specialized experience to mitigate common issues like thermal shrinkage and surface defects, ensuring your components are production-ready from the very first T1 trial.

Eliminating Warpage & Shrinkage

ABS is prone to deformation in complex geometries. We utilize advanced Moldflow simulation to optimize cooling channels and gate placement, ensuring ±0.05mm dimensional stability for parts up to 1,100 tons.

Flawless Surface Aesthetics

To prevent silver streaks and weld lines, we utilize engineered Fanuc high-speed machines and precision Mirror EDM (Ra 0.1um) to achieve Class-A finishes, ranging from high-gloss piano black to intricate VDI textures.

Specialized Material Blends

We excel in processing functional ABS blends, including ABS+PC for high toughness, Flame Retardant (UL94-V0) for electronics, and Heat Resistant ABS for demanding automotive environments.

High-Precision ABS Injection Molding Machine Specifications

Our facility integrates a versatile injection machine range with rigorous manufacturing standards to deliver unmatched component consistency. From large-scale industrial parts to high-precision electronics, we leverage advanced tooling technology and integrated secondary operations to ensure every project meets the most demanding engineering tolerances.

| Technical Category | GBM Specifications |

|---|---|

| Injection Machine Range | 50T to 1,100T (equipped for large & 2K parts) |

| Manufacturing Standards | IATF 16949 & ISO 9001 Certified Quality |

| Tooling Accuracy | Up to ±0.01mm with precision Mirror EDM |

| Specialized Processes | Insert Molding, Stack Molds, Unscrewing Molds |

| Secondary Operations | Painting, Silk Screening, Ultrasonic Welding |

High-Performance ABS Industry Applications

Successfully balancing functional durability with high-end aesthetic requirements demands a deep understanding of ABS material science. From heat-resistant automotive components to chemical-resistant medical housings, every manufacturing process is engineered to navigate the unique environmental and regulatory challenges of specific industries.

Automotive: Interior Systems

High-heat ABS formulations provide the essential dimensional stability and impact safety required for critical interior trims, dashboards, and mirror housings. These specialized materials are processed to meet stringent OEM durability standards and Class-A surface finish requirements.

Medical: Durable Enclosures

Medical-grade ABS enclosures offer long-term reliability against frequent sterilization cycles and exposure to harsh clinical cleaning agents. Careful material selection prevents stress cracking and polymer degradation, ensuring a safe and durable interface for diagnostic and laboratory equipment.

Electronics: Precision Housing

Class-A finishes, from high-gloss piano black to intricate VDI textures, provide the premium consumer appeal necessary for smart devices. Integrating Flame Retardant (UL94-V0) ABS guarantees that components meet global safety certifications without compromising on aesthetic excellence.

Rigorous Quality Control for Zero-Defect ABS Manufacturing

Ensuring consistency in industrial manufacturing requires more than just standard checks. Our quality management system integrates advanced metrology with certified process stability to deliver precision you can trust.

- Dimensional Precision & Inspection

Implementation of 100% electrode inspection and comprehensive CMM dimension reports ensures every component meets your exact engineering tolerances. FAI (First Article Inspection) samples are provided for client validation prior to mass production.

- Certified Process Reliability

Operating under IATF 16949 certified standards, we utilize CPK studies and scientific water-testing for mold cooling efficiency to maintain long-term production stability.

- Total Material Traceability

Guaranteeing 100% traceable material certifications for all raw resins and mold steel used in your project, ensuring transparency and compliance with global safety standards.

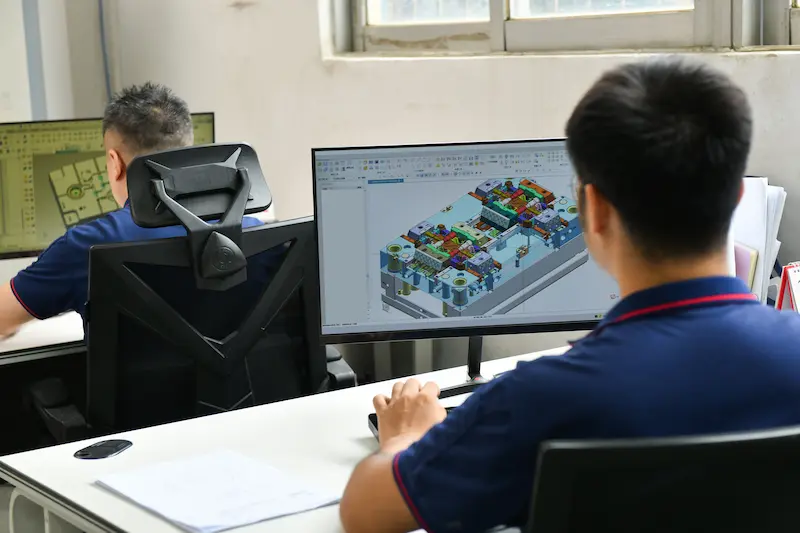

World-Class Manufacturing Facilities & Technical Specs

Equipped with top-tier precision machinery and an 1,800㎡ modern workshop, GBM provides a one-stop solution from complex mold design to high-volume injection molding. We ensure sub-micron accuracy and reliable lead times for global industry leaders.

| Feature | Specifications |

|---|---|

| Workshop Scale | 1,800㎡ Facility: A specialized workshop with 80+ experienced experts for mold making and injection. |

| Precision Equipment | Ra 0.1μm Surface Finish: Equipped with Makino Mirror EDM and Fanuc high-speed CNC for +/-0.01mm tolerances. |

| Production Power | 100T to 1,100T Presses: Capability for 2-shot, insert, and large-scale molds up to 5.5 tons. |

| Quality Control | 96% On-time T1 Rate: 100% electrode inspection and full 3D CMM dimension reports for every project. |

Rapid T1 Sample Delivery

Maintaining a 96% on-time delivery rate to keep your production on schedule.

Engineering Expertise

Proven track record with over 1,000 successful mold projects completed.

Material & Quality Assurance

100% traceable certifications for all raw resins and mold steel.

Common Questions About ABS Injection Molding

Explore our comprehensive FAQ guide to understand ABS material properties, processing techniques, and industry applications. Get professional insights to optimize your next manufacturing project.

Table of Contents

What is injection ABS?

- 1. The Triple-Monomer Advantage

- 2. Engineering Precision

- 3. Secondary Operations

What is ABS used for?

- 1. Automotive Industry

- 2. Consumer Electronics

- 3. Industrial & Toys

- 4. Healthcare

Which is better, ABS or PP?

What is the injection pressure for ABS?

- 1. Fill Stage

- 2. Holding & Packing

- 3. Back Pressure Management

Is ABS food safe?

- 1. Chemical Concerns

- 2. Thermal Limitations

- 3. Compliance Grades

How to injection mold ABS?

- Step 1: Scientific Drying

- Step 2: Precise Thermal Profile

- Step 3: Mold Temperature Optimization

- Step 4: Quality Validation

What is injection ABS?

ABS is an opaque engineering thermoplastic consisting of a rigid chemical blend designed for high-impact applications.

The Triple-Monomer Advantage: ABS combines Acrylonitrile for chemical and thermal stability, Butadiene for exceptional impact toughness (even at low temperatures), and Styrene for a rigid, glossy finish and excellent processability.

Engineering Precision: Unlike crystalline plastics, ABS is an amorphous material, meaning it has a lower and more predictable shrinkage rate (typically 0.4%-0.7%). This allows us to achieve tight tolerances of +/- 0.01mm using our Fanuc high-speed CNC and Makino EDM.

Secondary Operations: Its chemical structure makes it the best candidate for post-molding processes such as chrome plating, ultrasonic welding, and painting, making it a favorite for high-end aesthetic products.

What is ABS used for?

It is the “workhorse” of the manufacturing world, used whenever a balance of strength and surface quality is required.

Automotive Industry: Used for complex interior components like instrument panels, glove boxes, and center consoles, as well as exterior parts like radiator grilles and wheel covers that require UV-stabilized grades.

Consumer Electronics: The standard for laptop housings, keyboard keys (double-shot molding), and remote controls due to its scratch resistance and electrical insulation properties.

Industrial & Toys: Famous for being the sole material for LEGO bricks because of its incredible dimensional consistency. Also used for power tool housings that must withstand heavy vibration.

Healthcare: Used for non-invasive medical equipment covers and laboratory tool handles that require a non-porous, easy-to-clean surface.

Which is better, ABS or PP?

ABS is an “engineering plastic” for precision; PP is a “commodity plastic” for cost-effective flexibility.

| Performance Metric | ABS | PP |

|---|---|---|

| Mechanical Strength | Superior rigidity; resists deformation under load. | Flexible; exhibits high fatigue resistance (living hinges). |

| Precision Control | Low shrinkage; perfect for mating parts & complex assemblies. | High shrinkage; prone to warping and sink marks in thick walls. |

| Surface Aesthetics | Naturally glossy; excellent for painting/plating | Waxy feel; very difficult for adhesives or paint to stick. |

| Environmental Resistance | Moderate heat/chemical resistance; sensitive to UV. | Excellent resistance to acids, bases, and moisture. |

| Application Logic | Use for High-end Enclosures and Precision Gears. | Use for Hinged Containers, Totes, and Chemical Bottles. |

What is the injection pressure for ABS?

ABS has high viscosity and requires robust pressure (70-120 MPa) to fill complex mold cavities completely.

Fill Stage: We utilize a moderate-to-high injection speed to ensure the melt reaches the extremities of the mold before it begins to solidify, which is critical for thin-walled parts.

Holding & Packing: To combat the material’s natural tendency to shrink, a holding pressure of 30% to 60% of the peak injection pressure is maintained. This ensures the part remains dimensionally stable as it cools.

Back Pressure Management: A low back pressure (typically 5-10 bar) is vital during plasticization. Excessive back pressure can cause shear heating, leading to material degradation or “silver streaks” on the surface.

Is ABS food safe?

Not by default. Standard ABS contains chemicals that may migrate under heat, but specialized food-grade resins are safe for specific uses.

Chemical Concerns: Standard ABS may contain residual monomers or additives that are not approved for contact with fatty or acidic foods.

Thermal Limitations: Standard ABS should never be used in a microwave or dishwasher, as high heat can trigger the release of chemicals.

Compliance Grades: At GBM, we can source FDA-compliant or EU 10/2011 certified ABS for customers in the kitchen appliance or food storage industries. These resins are specifically formulated to be BPA-free and non-leaching.

How to injection mold ABS?

Success requires a “clean” process—dry material, stable temperatures, and high-precision machinery.

Step 1: Scientific Drying: ABS is hygroscopic (absorbs moisture). We dry the resin at 80°C – 90°C for 2-4 hours to reach a moisture content below 0.02%. Failure to do so results in internal voids and surface defects.

Step 2: Precise Thermal Profile: The melt temperature must be strictly controlled between 210°C and 260°C. If the temp exceeds 270°C, the material will turn yellow and lose its impact strength.

Step 3: Mold Temperature Optimization: We maintain mold temperatures at 40°C to 80°C. A higher mold temperature results in better surface gloss and lower internal stress, which prevents the part from cracking later.

Step 4: Quality Validation: After molding, every critical batch undergoes 3D CMM testing and a full dimension report to ensure that the shrinkage was perfectly managed.