- Home

- »

- PP Injection

Professional PP Injection Molding Solutions

16-Year Expertise in Custom PP Molding for Automotive, Electronics & Industrial Applications

- Optimized pp injection molding temperature for consistent quality

- Custom pp injection molds matching your design needs

- Compatibility with diverse pp injection moulding grade

- Transparent injection mold price & cost control

PP Injection Application Cases

You know, we once had a 500,000-piece run for automotive interior trims that almost went south because the shrinkage on the PP random copolymer was just a tiny bit off. That 0.3% compensation is everything. If you don’t have a guy on the shop floor who’s obsessed with the mold temp controller, those parts are going to warp the second they sit in a hot car for a few months.

It’s the same headache with food packaging—we’re doing over 200k units a month now. We kept seeing air bubbles in the early trials, and everyone thought it was the resin. Nope. Just bad venting. We widened the slots by a mere 0.1mm and dialed the injection temp to 190°C. Suddenly, the scrap rate hit zero.

Even for those flame-retardant housings that everyone says are too brittle at T1; usually, it’s just a matter of bumping the FR content by 2%. It’s not rocket science, it’s just about how the machines actually behave on the floor. Whether it’s auto, packaging, or electronics, the end product just has to work. Period. What are you looking to run?

Core Advantages of GBM Mold’s PP Injection Molding

Backed by 16 years of focused expertise in pp injection molding, GBM Mold delivers reliable, tailored PP injection solutions for automotive, electronics, and industrial sectors — integrating optimized pp injection molding temperature controls, custom pp injection molds for diverse pp injection moulding grade (including reliance pp injection moulding grade), and data-driven polypropylene injection molding parameters to address your production challenges.

16-Year PP Molding Expertise

With 16 years of pp injection molding experience, 300+ clients, and an in-house polypropylene injection molding parameters library, we partner with top PP suppliers (e.g., Reliance) for precise pp injection moulding grade mold design.

Cost-Effective PP Molding Solutions

We cut 8-12% material costs for pp plastic injection molding via bulk procurement, reduce 20% unit costs with optimized pp injection molding temperature, and offer free design consultation to avoid injection mold issues (saving rework costs).

Full-Cycle PP Molding Support

Enjoy 7×24 pp injection molding consultation (1hr response) and 48hr after-sales solutions (including pp injection molds rework). We also provide a free polypropylene injection molding guide for clients.

Certified Quality & Trusted by Top Brands

Our ISO 9001/IATF 16949-certified pp injection solutions support diverse pp injection moulding grade (e.g., pp random copolymer). We’ve served leading brands with stable ppt injection molding process results.

PP Injection Molding Process Flow

Pre-Production Material & Design Review

First, we check if your chosen PP injection moulding grade works with the part’s design specs. We also dry the material to get rid of moisture — that keeps bubbles out of finished parts. And every batch of incoming material goes through 100% inspection, no exceptions.

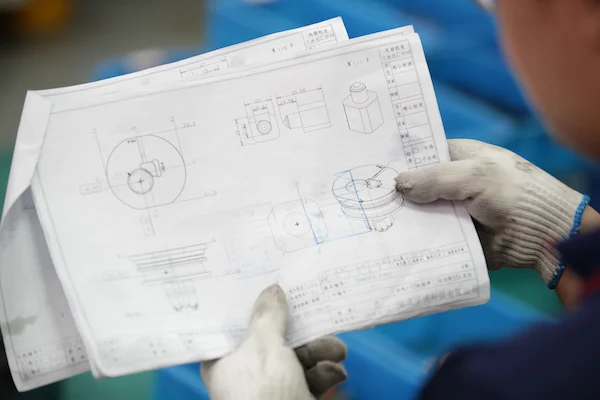

Mold Design & Fabrication

We build custom PP injection molds using 5-axis CNC machining, hitting a tight ±0.01mm tolerance. The final mold will line up perfectly with both your chosen PP grade and the exact specs of your part.

Parameter Setup & Trial Run

We tweak the PP injection molding temperature, plus fine-tune polypropylene injection parameters using real production data. Then we run trial molds: checking if the mold fits right, and if the part meets quality standards. Right now, our T1 trial success rate sits at 96%.

Production & Full-Batch Inspection

When we start mass production, Fanuc machines monitor parameters in real time. Every full batch goes through CMM dimension checks, so we can lock in consistent, high-quality output — no major defects in large runs.

Key Properties of PP for Injection Molding

Temperature Compatibility

A 170-220°C pp injection molding temperature (precisely adjustable via Fanuc injection machines) enables stable, low-warpage industrial parts — with no additional post-processing required.

Grade Flexibility

Compatibility with all pp injection moulding grade (reliance, pp random copolymer) supports tailored, application-specific solutions for automotive and medical sectors via professional sourcing.

Mechanical Performance

In-house tested high impact resistance delivers durable pp plastic injection molding parts for long-term use, meeting the most rigorous automotive load-bearing standards in critical applications.

PP Injection Molding: High-Performance Manufacturing Solutions

As a leading provider in precision manufacturing, GBM specializes in high-quality Polypropylene (PP) injection molding services. Known for its exceptional “living hinge” property and superior chemical resistance, PP is the material of choice for demanding applications in the automotive, medical, and consumer packaging industries.

Our state-of-the-art facility combines advanced cooling technologies with expert mold design to manage PP’s high shrinkage rates, ensuring every part meets your exact dimensional tolerances. Explore our technical FAQ below to learn how we can optimize your PP molding project for maximum durability and cost-efficiency.

Table of Contents

What is PP injection molding?

Is polypropylene good for injection molding?

- 1. Exceptional Fatigue Resistance

- 2. Superior Chemical Defense

- 3. Moisture Barrier

- 4. Cost-Efficiency

What does PP stand for in plastic?

What is PP grade?

What does PP stand for?

- 1. Chemical Structure

- 2. Monomer Source

- 3. Safety & Compliance

- 4. Surface Energy

Is PP better than PVC?

What is PP injection molding?

PP injection molding is a high-speed manufacturing process where molten polypropylene resin is injected into a precision-engineered mold. It is widely used for producing lightweight, chemically resistant parts.

| Technical Aspect | Description & Specification |

|---|---|

| Melt Temperature | 200°C – 280°C |

| Mold Temperature | 20°C – 60°C |

| Shrinkage Rate | 1.5% - 2.0% (High crystalline shrinkage) |

| Key Advantage | High flow rate, ideal for thin-walled complex geometries |

Is polypropylene good for injection molding?

Yes. It is highly valued for its “living hinge” property, low cost, and excellent moisture barrier, making it a top choice for consumer and industrial products.

Exceptional Fatigue Resistance: PP is the gold standard for “living hinges.” It can be flexed thousands of times without cracking or breaking.

Superior Chemical Defense: It remains stable when in contact with most acids, bases, and organic solvents, making it ideal for medical and laboratory use.

Moisture Barrier: With a near-zero water absorption rate, it provides an excellent barrier for food storage and electronic enclosures.

Cost-Efficiency: As one of the most affordable engineering plastics, it allows for high-volume production with a high ROI.

What does PP stand for in plastic?

In the plastics industry, PP stands for Polypropylene, a semi-crystalline thermoplastic addition polymer belonging to the polyolefin family.

| Feature | Details |

|---|---|

| Full Name | Polypropylene |

| Polymer Type | Semi-crystalline Thermoplastic |

| Recycling Code | #5 (PP) |

| Chemical Family | Polyolefin |

What is PP grade?

PP grades are specific formulations optimized for different stiffness, clarity, or impact requirements..

Homopolymer PP: The most common grade. It offers high stiffness and heat resistance, widely used in textiles and general packaging.

Random Copolymer PP: Produced by adding small amounts of ethylene. It has superior clarity and flexibility, perfect for transparent food containers.

Impact Copolymer PP: Features a higher ethylene content. It provides exceptional toughness even at low temperatures, commonly used for automotive bumpers.

Medical Grade PP: Specifically formulated to remain stable during sterilization processes such as autoclaving or gamma radiation.

What does PP stand for?

Technically, it stands for Poly(1-methylethylene). It is a polymer made from the monomer propylene C₃H₆ via chain-growth polymerization.

Chemical Structure: A linear hydrocarbon chain represented by the formula (C₃H₆)ₙ.

Monomer Source: Derived from propylene gas, which is a byproduct of petroleum refining.

Safety & Compliance: Naturally BPA-free and non-toxic, it is one of the safest plastics for food contact and skin sensitivity.

Surface Energy: It has a low surface energy (non-polar), meaning it requires surface treatment if it needs to be painted or glued.

Is PP better than PVC?

“Better” is application-specific. PP is superior for food safety and weight, while PVC is better for flame retardancy and structural rigidity.

| Feature | Polypropylene (PP) | Polyvinyl Chloride (PVC) |

|---|---|---|

| Heat Resistance | Up to 110°C (Superior) | Low (Softens at 70°C) |

| Density / Weight | Low (Floats in water) | High (Sinks in water) |

| Eco-Friendliness | Highly recyclable & Chlorine-free | Challenging; contains Chlorine |

| Flexibility | Naturally flexible (Living hinges) | Requires plasticizers for flexibility |

| Typical Use | Food containers, medical parts | Pipes, window frames, flooring |