- Home

- »

- Precision-Mold-Making

GBM Mould | Precision Injection Mold Manufacturer Since 2010

With ±0.005mm tolerance precision, 5.5 ton mold capacity, and trusted by leading brands like PHILIPS & BOSCH, GBM Mould delivers high-quality precision injection molds tailored to automotive, medical and electronic industries.

Get detailed quote + free DFM review in 12 hours

2010

Established Year

1800㎡

Workshop Area

80+

Professional Team

1000+

Molds Completed

96%

On-Time T1 Rate

Precision Mold Manufacturing: Core Solutions

GBM delivers precision mold solutions engineered for accuracy, durability, and efficiency—backed by advanced tech (5-axis CNC, CMM inspection) and tailored to auto, medical, and electronic industries. Explore our key mold types below.

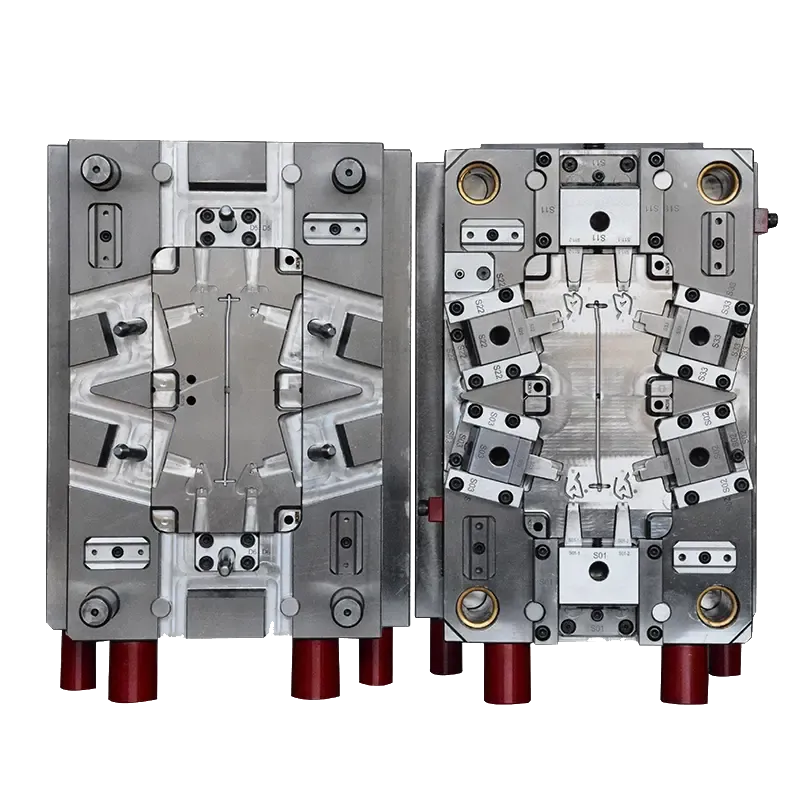

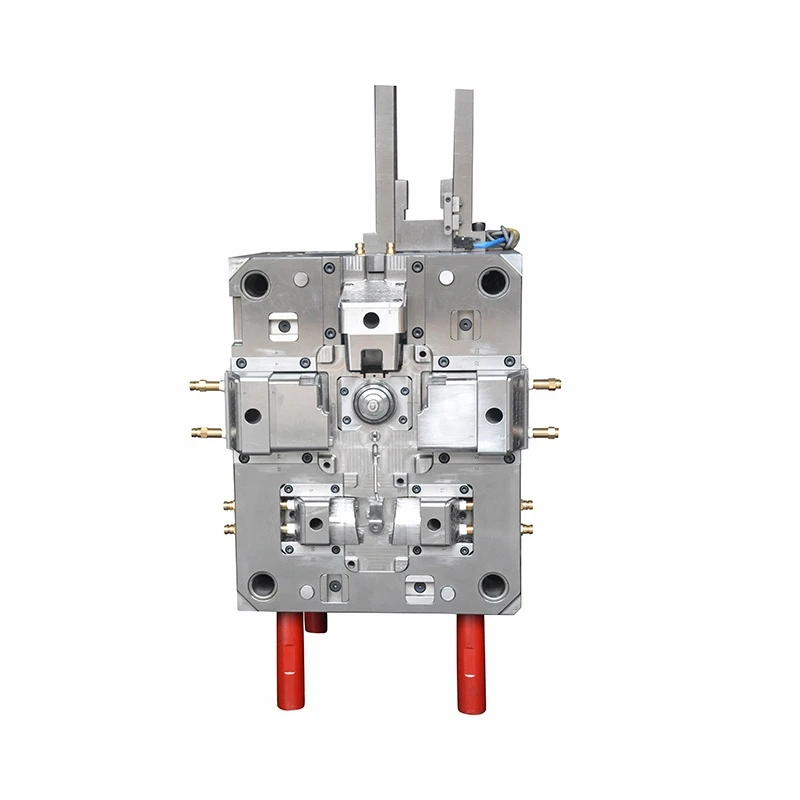

High-Accuracy Precision Plastic Mold

Features ±0.005mm tolerance (supported by Hexagon CMM inspection) and 500k+ shot life. Compatible with PP/PC/ABS materials; ideal for high-volume, dimensionally stable plastic parts (e.g., auto components, consumer products).

Dual-Material 2-Shot Mold

Produced with 1100-ton machines; ensures excellent material bonding (key for parts like toothbrush handles). Reduces assembly steps via one-step molding—optimizing efficiency for multi-material components.

Metal-Plastic Insert Mold

Enables metal-plastic combination (e.g., electronic connectors, gears) with high-strength bonding. Supports 1480+ inserts; delivers durable parts via precision assembly (backed by modular design).

Automated Unscrewing Mold

Creates threaded parts (bottle caps, lids) via automated rotating mechanisms. Reduces labor costs; unique unscrewing feature (not available in standard molds) ensures efficient demolding.

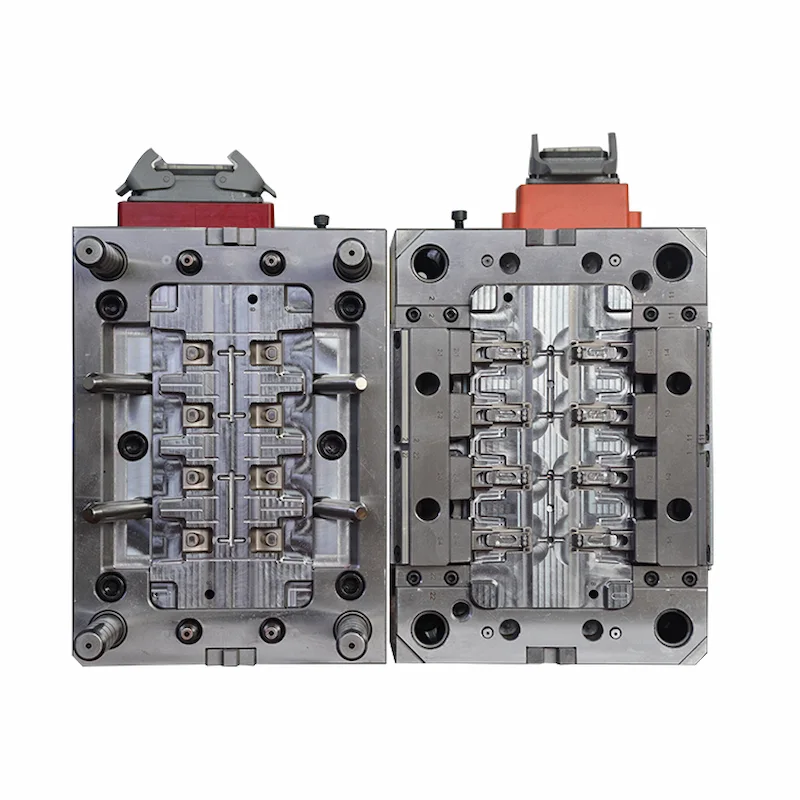

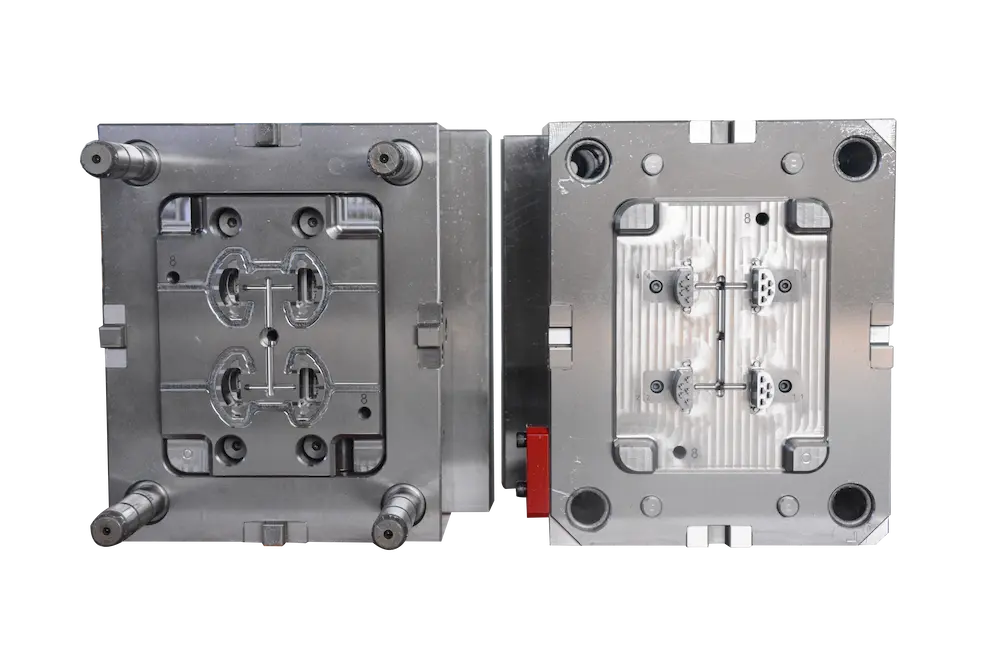

High-Cavity Stack Mold

Features 2-32 cavities for high output; 9-week fast delivery. Reduces material usage by 1.5x (via optimized design) — balancing production efficiency and cost control.

Why Choose GBM Mould? Your One-Stop Precision Molding Partner

Founded in 2010, we provide end-to-end solutions from product analysis, DFM optimization to mold manufacturing, injection molding and mass production. With 12 senior engineers and world-class equipment (Yamazen 5-axis CNC, Hexagon CMM), we specialize in high-temperature materials (PEI/PPS/PEEK) and complex molds for automotive, medical and electronic industries. ISO 9001 & IATF 16949 certified, we ensure 98% on-time delivery.

- ±0.005mm Precision | Hexagon CMM Inspected

- 9-45 Days Lead Time | Stack Molds in 9 Weeks

- 5.5 Ton Capacity | Large & 2-Shot Molds

- ISO 9001/IATF 16949 | Auto/Medical Qualified

DFM-Optimized Mold: 4 Success Stories

For over 17 years, GBM Mould has delivered tailored precision mold solutions to automotive, medical, electronic and heavy-duty industries. Below are 4 representative cases where we addressed core pain points (e.g., breakage, long lead times, tight tolerances) with our 5-axis CNC machining, DFM optimization and modular design capabilities.

Korean Auto Client | 1480 Inserts Mold (±0.01mm)

The client’s auto thin-wall parts kept breaking during injection, caused by uneven stress in the mold cavity. We optimized the cavity structure with 5-axis CNC machining and adjusted the gating system to balance pressure.

- Tolerance: ±0.01mm

- Outcome: Fixed breakage issue

- Efficiency: T1 trial approved | 800k+ shot life

U.S. Medical Client | PEEK Mold (100k Cleanroom)

The client needed FDA-compliant PEEK medical parts but struggled with stability and contamination risks. We used H13 steel and produced in a 100k cleanroom with 5 rounds of CMM inspections.

- Compliance: FDA certified

- Output: 10k+ monthly production

- Quality: 0 defects in 6 consecutive months

Chinese Electronics | Stack Mold for Connector

The client faced long lead times (30+ days) and high material costs for small connector parts. We designed a 4-cavity stack mold and adopted a parallel machining process to compress the timeline.

- Lead Time: 9 weeks (70% reduction)

- Cost Saving: 1.5x material efficiency

- Cavity Design: 4-cavity stack structure

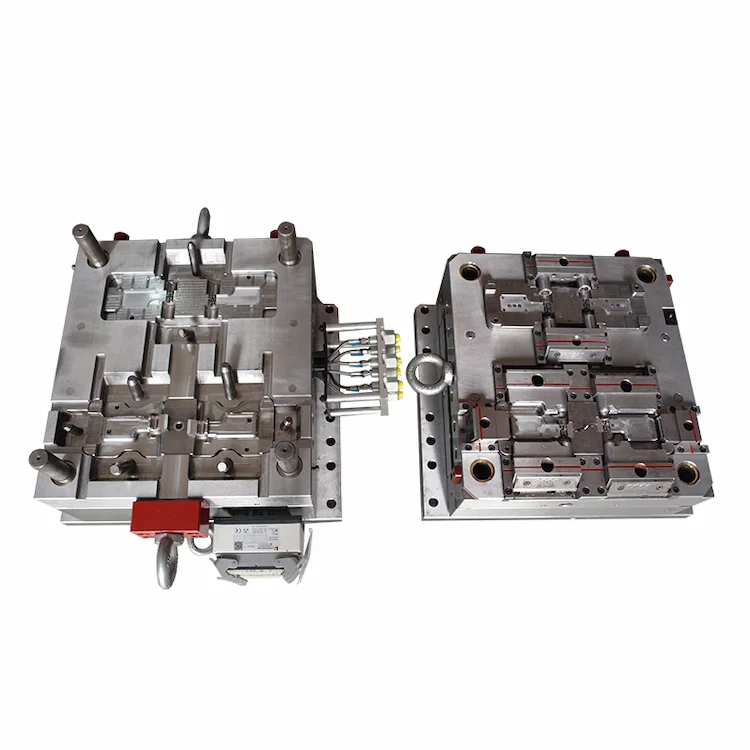

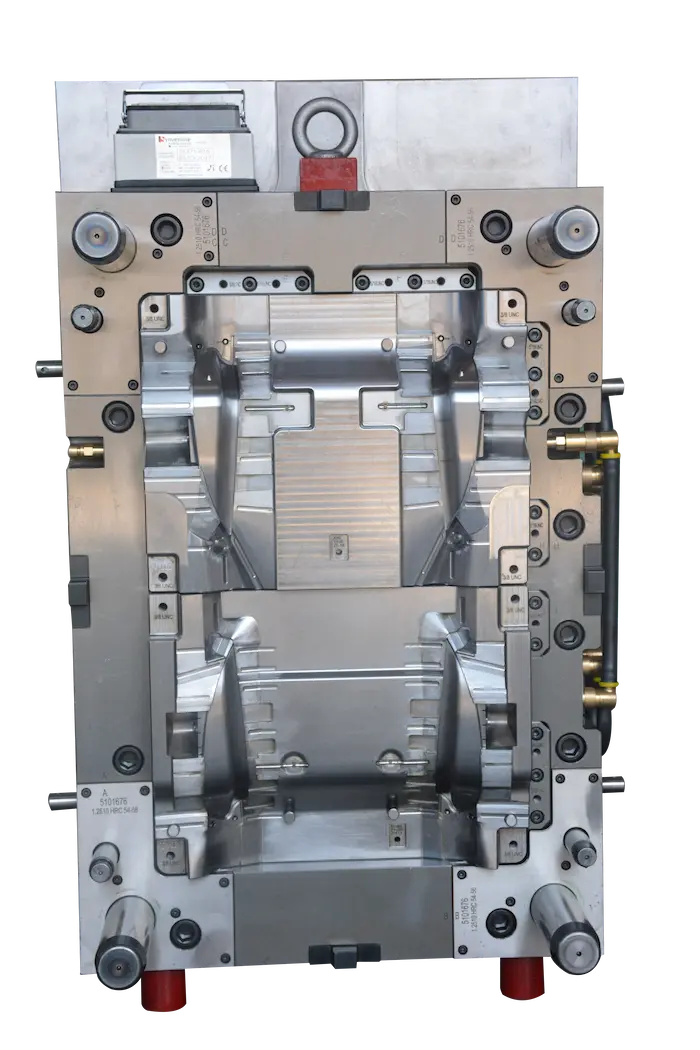

European Client | 5.2 Ton Auto Mold

The 5.2-ton large auto mold required tight ±0.008mm tolerance, but complex alignment issues delayed assembly. We used 5-axis CNC for large cavity machining and a modular assembly design to ensure precision.

- Tolerance: ±0.008mm

- Assembly: 1-time success

- Durability: 800k+ shot life

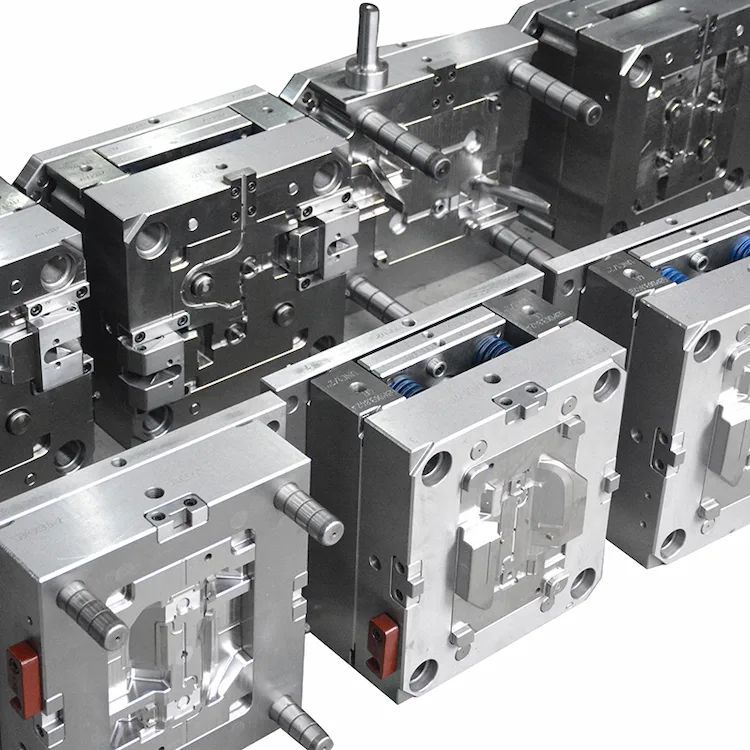

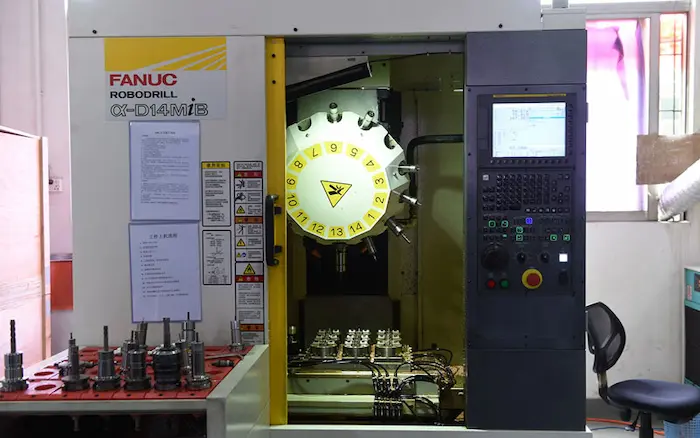

Advanced Tech & Equipment: The Core of Precision Molding

At GBM Mold, our superior mold precision relies on industry-leading technology and equipment. We integrate high-end machining, strict quality control, and professional injection capabilities to deliver consistent, high-accuracy solutions—backed by custom design and simulation tools that minimize trial risks.

Precision Machining

- Yamazen/YCM 5-axis CNC (15000-24000rpm)

- AgieCharmilles Wire EDM (±0.001mm)

- Handles Complex Cavities & 5.5 Ton Molds

Quality Control

- Hexagon CMM, ±0.001mm Precision

- 5+ 3D Inspections

- CPK/FAI Reports Provided

Injection Molding

- Fanuc/Haitian Machines

- High-Temp Material (PEI/PPS/PEEK) Compatible

- Transparent Plastic Specialized

Production Process Full-Link Precision Manufacturing

From demand docking to finished product delivery, we have established a standardized and refined production control system. With strict processes, we ensure the precision and stability of each set of molds, accurately meeting the high-end customization needs of multiple industries.

Demand Analysis & Design

One-on-one in-depth docking with customers to analyze product drawings, material requirements and tolerance standards; combined with mold flow simulation technology, output 3D mold design schemes and detailed process plans to avoid molding defects in advance.

Material Selection & Inspection

Select high-quality mold steels such as S136 and H13, pass strict quality inspection processes including hardness testing and purity analysis, eliminate unqualified raw materials, ensure stable performance of raw materials, and lay a solid foundation for high service life and high precision of molds.

Precision CNC Machining

Adopt 5-axis linkage CNC machining centers for high-precision cutting of core components such as mold bases and cavities; cooperate with CMM for real-time and accurate inspection, strictly controlling dimensional tolerance within ±0.005mm to ensure machining precision and consistency.

Refined Mold Assembly

Led by senior technicians with more than 10 years of experience, strictly control assembly clearance, guiding precision and accessory fit; record parameters throughout the assembly process to ensure each assembly link meets process standards and guarantees the overall performance of the mold.

Trial Molding & Optimization

Install the assembled mold on the injection molding machine for trial molding, collect data such as size and surface quality of molded products; optimize injection molding process parameters according to trial results until products fully meet customer drawing requirements and quality standards.

Final Inspection & Delivery

Conduct comprehensive quality inspection on finished molds, covering core indicators like dimensional precision, surface finish and service life; issue authoritative reports post-inspection, perform professional packaging, deliver accurately, and provide technical guidance and after-sales support.

FAQs

What is the tolerance accuracy of precision injection molds?

The tolerance of our precision injection molds can be stably controlled within ±0.005mm. Relying on the full-process inspection of 5-axis CNC machining centers and coordinate measuring machines, combined with high-quality mold steels such as S136 and H13, we can meet the customization needs of high-precision industries such as automotive and electronics.

What are the key factors affecting the service life of injection molds?

The service life of injection molds is mainly affected by three core factors: first, the material performance of mold steels such as S136 and H13; second, refined processing and assembly technology; third, post-maintenance and usage specifications. We provide customers with professional mold maintenance guidance to extend mold service life.

How long does it take to develop a custom injection mold?

The development cycle of conventional structure injection molds is 15-30 days, and that of complex multi-cavity and precision insert molds is 30-45 days. Through our standardized production process, we maximize the shortening of delivery cycles on the premise of ensuring quality.

What are the common reasons for injection mold trial failure?

Common reasons for injection mold trial failure include: product size deviation caused by insufficient cavity machining precision; improper matching of injection process parameters (temperature, pressure, injection speed); product deformation caused by unreasonable cooling system design. Our engineers will quickly troubleshoot and optimize parameters to ensure product compliance.

How to choose the right mold steel material for injection products?

Mold steel selection should be based on product characteristics: P20 steel is cost-effective for ordinary plastic products such as PP and PE; S136 stainless steel is preferred for high-precision or corrosion-resistant products; H13 hot work mold steel is recommended for high-temperature engineering plastics such as PA66. We provide free material selection solutions.

What is the importance of cooling system design for injection molds?

The cooling system is a core component of injection molds. It can precisely control mold temperature, shorten product molding cycles, reduce defects such as plastic part shrinkage and warpage, while reducing mold heat loss and extending mold service life. We customize efficient cooling solutions according to product structure.

What are the core advantages of multi-cavity injection molds?

Multi-cavity injection molds can inject multiple products at one time, greatly improving production efficiency and reducing unit product cost, which is suitable for mass production of standardized products. We can customize high-efficiency mold solutions with 2-32 cavities to meet different production capacity needs.

What after-sales guarantee services are available after injection mold delivery?

We provide 1-year free warranty service and lifelong technical support. If the mold malfunctions, engineers can guide debugging remotely and provide on-site maintenance if necessary. We also conduct regular customer follow-ups and provide professional mold maintenance suggestions.

Partner with GBM for High-Precision Excellence

Join 1,000+ global industry leaders who trust GBM for quality, durability, and on-time delivery. Let’s turn your complex concepts into high-quality reality.